It’s no surprise that the business, commercial, and industrial world is wide awake to the benefits of modern flow sensors. While meters or sensors that measure the mass or flow of liquids or gases are not new, the innovation of the past years has been meteoric.

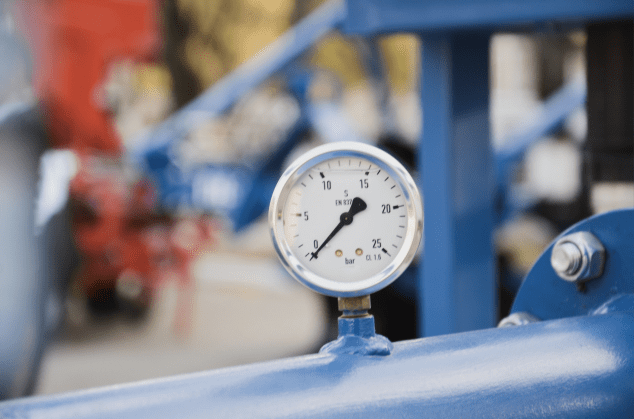

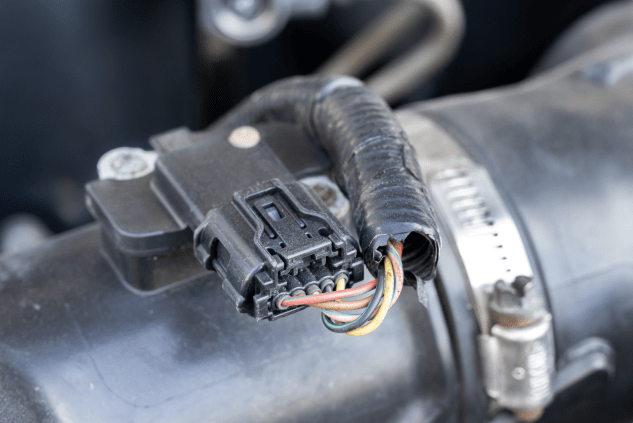

For those new to this technology sector, it is surprising to realize how widely deployed and critical flow sensors have become to those businesses needing to monitor the efficiency of their flow-related operations. Businesses can measure sales of their products with high accuracy, or deploy a flow sensor in another way – like knowing when a pipe is leaking. Understanding flow with great detail also boosts safety, as pressure and velocity changes can be known immediately. Flow sensors are now crucial to the oil and gas industries; they’re found in petrol pumps and distilleries; they’re fitted to engines; a water flow meter is how your utility company calculates your bill; they ensure precisely the right amount of chemicals and ingredients are in your medicines, food, and drinks – and so on. They help to protect the environment, optimize your processes, boost product quality, cut costs – and the rise in demand in this fascinating technology sector grows by the day.

And with that level of usefulness and deployment, research, development, and innovation simply soar. While a flow sensor might once have been quite rudimentary, now they incorporate digital signals, multiple measurement formats, real-time diagnosis and troubleshooting, remote calibration, advanced features like online alerts, and wireless connectivity – and the list just keeps on growing.

But what are the latest innovations that are really turning heads? Here are our top 3:

Contents

1. Self-cleaning

While the advantages of flow sensors are patently obvious, one of the downsides is that they need regular, meticulous, and often complex cleaning to keep them working properly for longer. So it’s no surprise that flow sensor innovators have put a lot of R&D into automated or self-cleaning technology. Water, gas, and steam can be particularly ‘dirty’, so self-cleaning mechanisms slash downtime, maintenance costs, inaccuracies, and failures as these advanced devices rid themselves of contaminants without needing to be uninstalled. And when you consider that manually cleaning, for instance, a wastewater flow meter can be hazardous, technology that actively guards against blockages and build-ups in the system are worth their weight in gold.

2. Advanced software

Once upon a time, the flow sensor was much more of a purely mechanical device – so it’s not difficult to imagine the impact of the rapidly advancing world of computer processing has been. Powerful chips that can process data with incredible accuracy and speed is revolutionizing the flow sensor industry, driven on by an even faster-moving world of software. Parameters can be modified and customized by the actual user, while the software interfaces are ever more powerful but also easier to use.

3. Advanced features

But these advanced features go beyond mere software, and deep into the heart of the overall design of modern flow sensors. It has made the devices themselves highly sophisticated but also increasingly affordable for businesses across the spectrum, not to mention ever lighter, easier to maintain, replace, and operate. Users can customize them, connect and integrate them wirelessly, and explore a vast world for analyzing and reporting about the information they are monitoring and recording. It makes them more accurate, incredibly cost-effective, flexible, and ultra-reliable.

So as flow sensor innovation runs apace, demand goes up – for every single business operation, and even into the home. If your operation’s flow sensor deployment is out of date, or you think the technology sector’s latest advancements have finally put it within your reach, talk to an expert about choosing the right ones today.